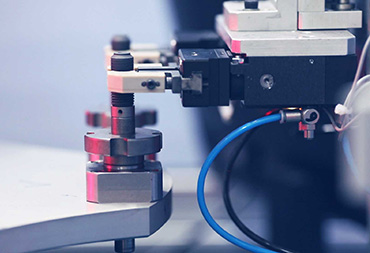

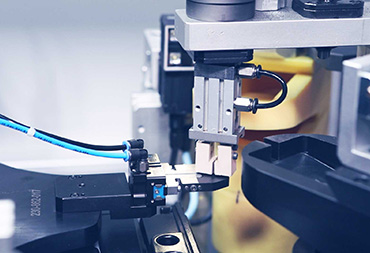

We love the minds of machines that can follow themselves and interact with other machines. We design all our special machines in a way that they can communicate with other machines and allow remote monitoring by their users.

Moving to the "Full Intelligent Manufacturing" model in the very near future is our most exciting goal. We take our production development capabilities to a new level, increase our efficiency and savings with our investments in industry 4.0; however, more importantly, we aim to design machines that can anticipate maintenance needs and operate without errors throughout their lifetime through digitalization in our production.